A team of researchers at Dartmouth College in New Hampshire has devised an innovative flexographic printing method that holds the potential to expedite the manufacturing of Perovskite solar cells with increased efficiency and reliability. This breakthrough technique brings the prospect of cost-effective mass production of solar cells closer to reality. Perovskites, possessing the same crystal structure as the mineral calcium titanium oxide, exhibit promising attributes for high performance and low production costs in solar cell creation. The findings of this research are detailed in a study titled “Eliminating the Perovskite Solar Cell Manufacturing Bottleneck via High-Speed Flexography,” published in Advanced Materials Technologies.

The study’s authors include Julia Huddy, a third-year PhD student at Dartmouth, Youxiong Ye, a former postdoctoral researcher at the university now working as a metallurgist, and William Scheideler, Assistant Professor of Engineering at Dartmouth.

Currently, commercially produced solar panels predominantly employ silicon-based solar cells, a process requiring high-purity silicon with significant energy consumption, hazardous solvents, and high costs. In contrast, Perovskite cells consist of layers of tiny crystals made from affordable light-sensitive materials. These materials can be blended into a liquid form, serving as an ink that can be printed onto various substrates.

Professor William Scheideler envisions a combination of traditional solar applications, such as utility-scale and residential rooftop solar, along with non-traditional uses in electric vehicles and mobile devices, citing the strategic advantages of Perovskite cells in terms of lightweight and flexibility.

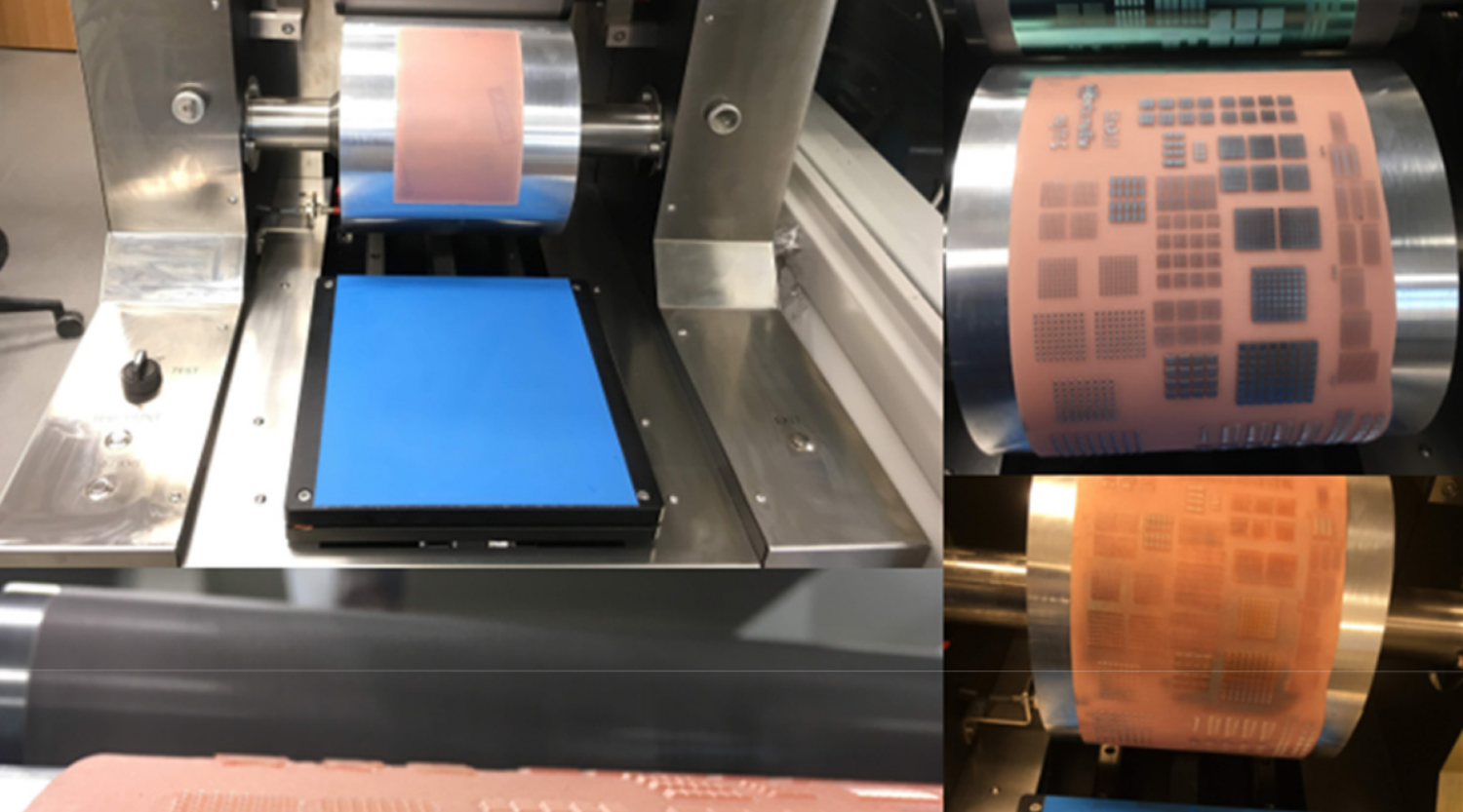

The efficiency of Perovskite solar modules, while promising, faces challenges in scaling due to slow production times and elevated manufacturing costs. The newly developed printing method at Dartmouth combines high-speed flexography, utilizing flexible printing plates, and sol-gel inks composed of Perovskite crystals. This integration accelerates material processing times by a remarkable 60 times, as per the study.

While acknowledging the progress, Scheideler notes that overcoming challenges, such as scaling up transparent electrodes and designing more flexible and robust materials, remains crucial for future advancements. Additionally, addressing the cost associated with vacuum deposition of metal electrodes is identified as a milestone to facilitate large-scale production of Perovskite solar energy.